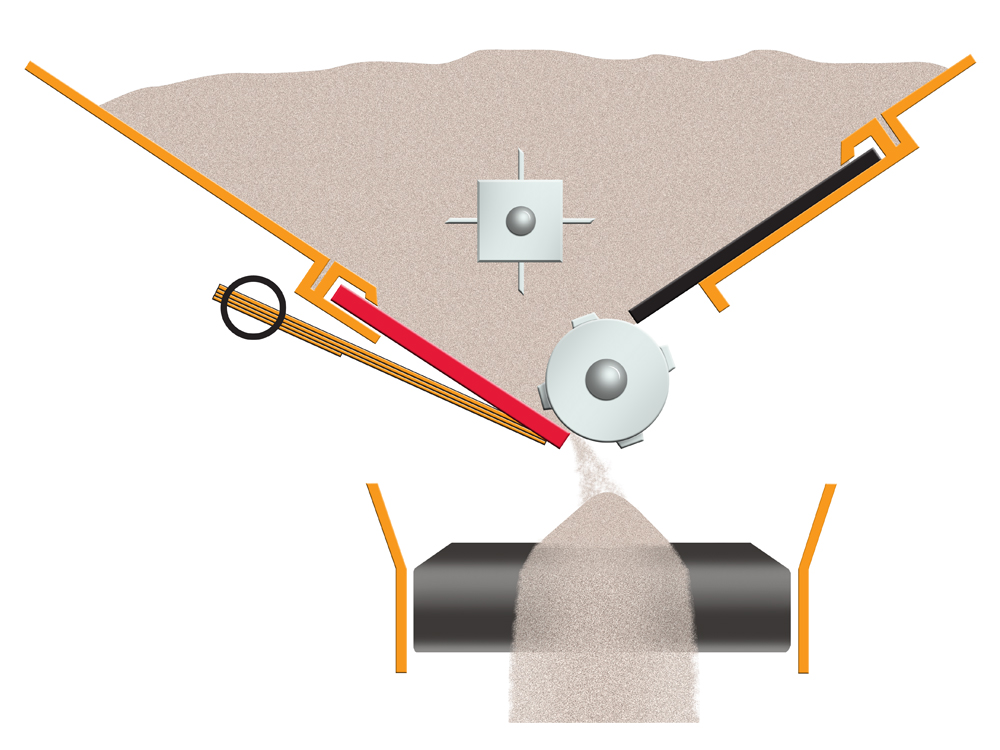

The Epoke Principle consists of:

- An agitator, which prevents material bridging and crushes large lumps ensuring accurate material supply.

- A delivery roller, which further ensures accurate and consistent delivery to the conveyor belt.

- An unladen rubber conveyor belt, which moves the precisely metered quantity to the spreading disc.

Advantages:

- Low spreader starting torque because the conveyor belt never carries more than 20 pounds of material, versus the 1,000s of pounds that rest on the chain conveyor of a conventional spreader.

- Minimal wear - serviceable

- Uniform hopper emptying which maintains a stable center of gravity

This precision-oriented method maintains consistent delivery of material to the spreader disc.

Width of spread and quantity of material are controlled by an electronic-over-hydraulic system which also has manual overrides.

Operators can easily monitor and change width and quantity settings in-cab with the EpoMaster remote control system.